LUMINEQ transparent displays can be fully sealed stand-alone units, or as displays ready to laminate into larger sheets of glass – what we call our in-glass/polycarbonate laminated displays.

Follow this page or watch the video below to get a better understanding of our display technology, laminated glass in general, and how to marry the two technologies for exciting new possibilities in design and function.

LUMINEQ display structure

LUMINEQ displays consist of a glass panel, an electronic control circuit and a power supply. The glass panel consists of an inorganic luminescent phosphorous layer sandwiched between transparent dielectric layers and a matrix of row and column electrodes as shown in this drawing.

A pixel on the display is lit by applying voltage to the row and column electrodes, thus causing the area of intersection to emit light.

The result of this solid-state design is a bright, reliable and inherently rugged display. LUMINEQ displays are available in either monochrome yellow or green.

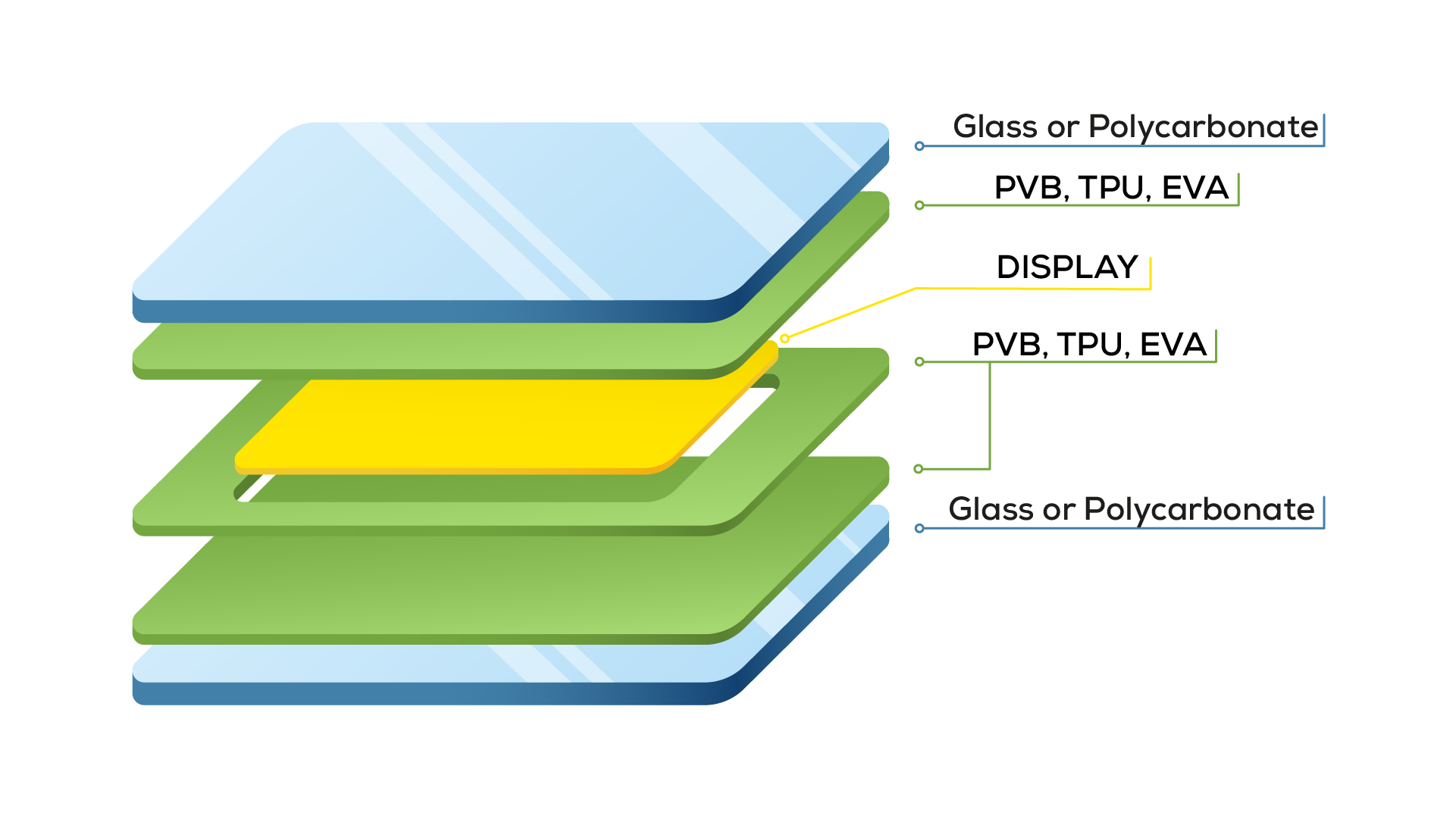

Laminated glass is made of two or more pieces of annealed glass held together by an interlayer, typically of polyvinyl butyral (PVB), ethylene-vinyl acetate (EVA), or thermoplastic polyurethane (TPU).

To manufacture laminated glass, annealed glass is stacked with the plastic interlayer, which is then passed through a series of rollers or vacuum bags and heated using an autoclave to expel any air pockets and to achieve the final bonded product.

The basic structure of laminated glass

Laminated glass when broken

With laminated glass, there are some great features.

Increased safety comes from a harder to break glass structure and if it does break, it typically stays together rather than shattering everywhere.

The interlayer reduces sound as well as solar energy and controls UV radiation.

It's more durable, maintains its color and also has a lot of versatility – you can add technology such as wires for defrosting or antennae.

Our displays, which are 0.7mm thick match well to be embedded into a full thickness PVB which is 0.76mm thick.

LUMINEQ display thickness of about 0.7mm thick, works very well to be embedded into a layer of 0.76mm PVB. The displays are shipped with the layers of thin films exposed – without a cover glass – so they are optimized for lamination.

LUMINEQ displays easily handle the lamination process pressure of 8-14 bar and temperature of roughly 140 degrees Celsius.

The displays can accept a slight compound curve during the lamination process – so you don't have to have a flat piece of glass to use our display technology in.

To get started, we recommend our lamination introduction packages using one of our standard displays. We have lots of options for design, this one on the right being one of them.

The lamination introduction package includes dummy glass, dummy glass with flex, as well as our display glass with the drive electronics.

We'll provide the file for the laminator to use to cut the interlayer to match our display and suggest that the laminator practice first with just the glass samples, then the glass samples with flex and finally with the displays provided.

The first proof of concept is typically done with a standard product to lower initial costs and to do tests, then the customer can work with our team on a custom display solution that fits their needs perfectly.

No experience working with laminated glass or laminators? Not an issue as we've had the opportunity to work with most of them and happily will introduce you to the teams we think fit your needs most.

If you have preferred vendors, we are glass and laminator agnostic and will support you how you need us to. We also have a best practices laminated displays document that will help you get going quickly.

Subscribe to our newsletter and get updates on the latest display technologies and industry trends.